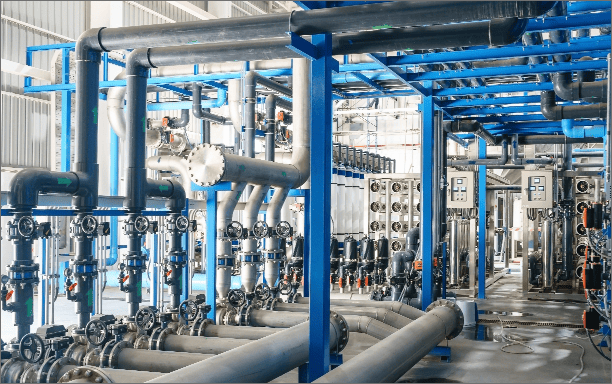

Pre-Treatment & Filtration Systems

Pre-treatment systems

The objective of the pretreatment process is to improve the quality of feed water. It is done before the main process to protect the more sensitive downstream process units whose efficiency may be severely affected by untreated raw water. We offer a wide range of pre-treatment systems that make the feed water suitable for downstream processes and operations.

Our range of pre-treatment plants comprises...

•Clarifiers & Flocculators

•Tube settlers

•Lamella Clarifiers

•High-Rate Solid Contact Clarifiers (HRSCC)

Filtration systems

Filtration systems are employed to remove minute particles from the feed water through ne physical barriers. Our extensive range of filtration systems is designed to cater to varied requirements. We offer manual, automatic, and remotely operated systems. The systems offered in different MOCs like FRP, MSEP, MSRL, or SS construction are suitable to the application requirement. Our comprehensive range of filtration systems consists of...

Dual media filter/ multimedia filter

These filters use depth filtration techniques to remove turbidity and minute suspended solids from feed water. We offer high-performance dual media filters using quartz-grade sand and anthracite as the principal filtration media supported by pebbles of various sizes, Silex, and crushed gravel to filter out the turbidity and suspended solids. These filters employ a bed of anthracite at the first level where initial coarse filtration is done, followed by a sand bed filter that provides twice the dirt-holding capacity achieving high performance.

Activated carbon filter

The activated carbon filters are used to remove organic contaminants from water by adsorption. The principal media activated carbon, is an extremely porous media that adsorbs organic colloids often present in raw water, thereby rendering it odor-free and also helping the removal of color.

Waterworks offers a wide range of advanced filtering systems to fulfill various types of industrial, commercial, and domestic applications. Waterworks carries out designing, supplying, and installing the most suitable and cost-effective filtering systems with superior after-sales service to make sure the clients meet their expectations all the time.

Microfiltration systems

Micro-filtration removes in the range of approximately 0.1 to 1 micron. Effective in the removal of bacteria, occulated materials, TSS & large colloids. However macro-molecules and dissolved solids pass through the MF membrane. Transmembrane pressures are typically 10psi (0.7 Bar).

Ultra-Filtration (UF)

Ultra-filtration provides separation of particles up to 0.1 microns. All dissolved salts and smaller molecules pass through the membrane. Items rejected by the membrane include colloids, proteins, microbial contaminants, and large organic molecules. Transmembrane pressure is typically 1 to 7 Bar.

Nano-Filtration (NF)

Nano-filtration refers to a specialty membrane process that rejects particles in the approximate size range of 1 nanometer. Applications include the removal of color and total organic carbon (TOC) from surface water, removal of hardness, and overall reduction of total dissolved solids (TDS).

Social Media

Together, let’s ensure every drop counts - partner with Waterworks for a cleaner, brighter tomorrow.

2025 © All rights reserved. Design & Develop by Sha Web Design